From Downhole to Surface, we build artificial lift and pump systems engineered to outlast and outperform – backed by quality aftermarket services.

Horizontal Pumping Systems

HPS

Our Slyder Horizontal Pumping System is a low maintenance, high performing pump solution for high pressure fluid movement and maximum performance in oil production.

- Designs to 100,000 BPD

- Pressures to 6,000 psi

- Lower costs than gear driven/positive displacement/vertical turbine pumps (both operational & maintenance)

- Application & design expertise

- Front-pullout and back-pullout designs

- Choices of various seal options

- Remote SCADA Monitoring & optimization

- Comes standard with transducer-type pressure gauges and on-skid instrumentation wiring

- Complete Installation services

- Regularly scheduled Inspection and preventative maintenance

- Water injection/disposal

- Water transfer

- Dewatering applications

- Amine

- Natural Gas Liquids

- Liquid CO2

- Crude oil transfer/boosting

ANSI Pumps

ANSI

These centrifugal pumps are horizontal, end suction, single stage pumps that are similar in size and identical in interface. While a vast majority of these pumps are used in the chemical industry, ANSI process pumps are also used in breadth of industries including oil and gas, mining, water resources, chemical processing, power generation and various other process plant applications.

- Flows to 1400 m³/h (6160 gpm)

- Heads to 220 m (720 ft)

- Pressures to 25 bar (365 psi)

- Temperatures from -80°C (-110°F) to 400°C (752°F)

- Oil & Gas

- Mining

- Water Resources

- Chemical Processing

- Power Generation

- Various process plant applications

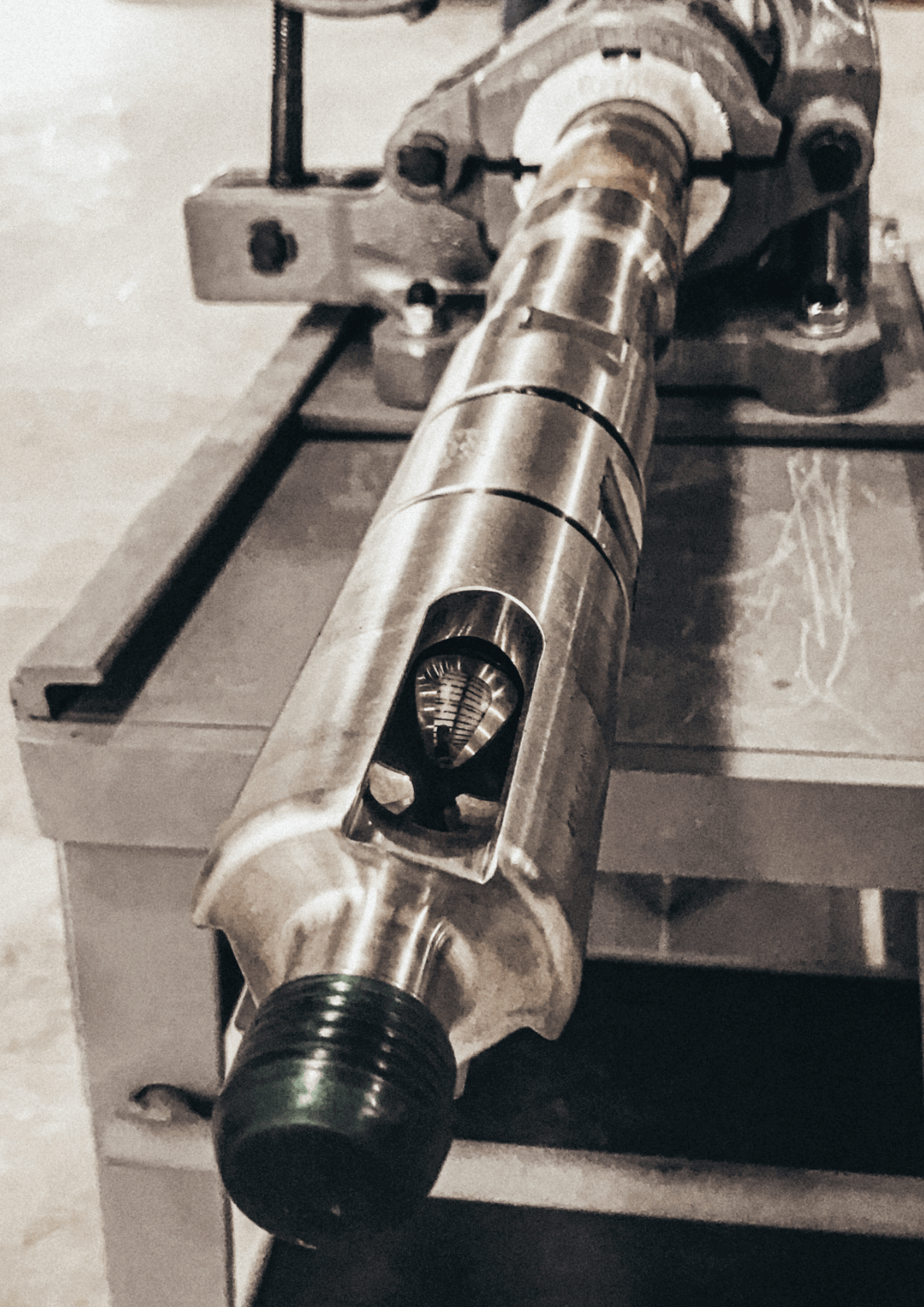

Sucker Rod Pumps

SRP

Slyder Sucker Rod Pumps are maximizing oil production with quality products, state-of-the-art technology and US-based manufacturing facilities. All SRPs are guaranteed an annual warranty and are backed by quality aftermarket services for the lifetime of your pumps. Maximize your performance, reduce overall maintenance costs and costly downtimes. Contact our Slyder Experts today to see the technology in action.

Electric Submersible Pumps

ESP

Slyder’s Electric Submersible Pumps (ESPs) are built to withstand the test of time, pressure and provide maximum performance. Our ESPs are engineered for efficiency and reliability of the system in the toughest downhole conditions. We can help you produce at rates from 60 to 168,000 B/D at temperatures up to 260°C (482°F) and pass through buildup rates up to 25° per 100 ft to get closer to the reservoir.

Whether your challenge is high gas and/or abrasive content in the fluid stream, high downhole temperatures, costly interventions, or a rapid production decline curve, our experts can recommend the best solution to keep your well on production.

Variable Frequency Drives

VFD

Reduce power peaks and automatically control your motor speed. Run at full horsepower only when necessary and get the maximum performance out of your pump system. The result is lower energy costs and increased oil production.

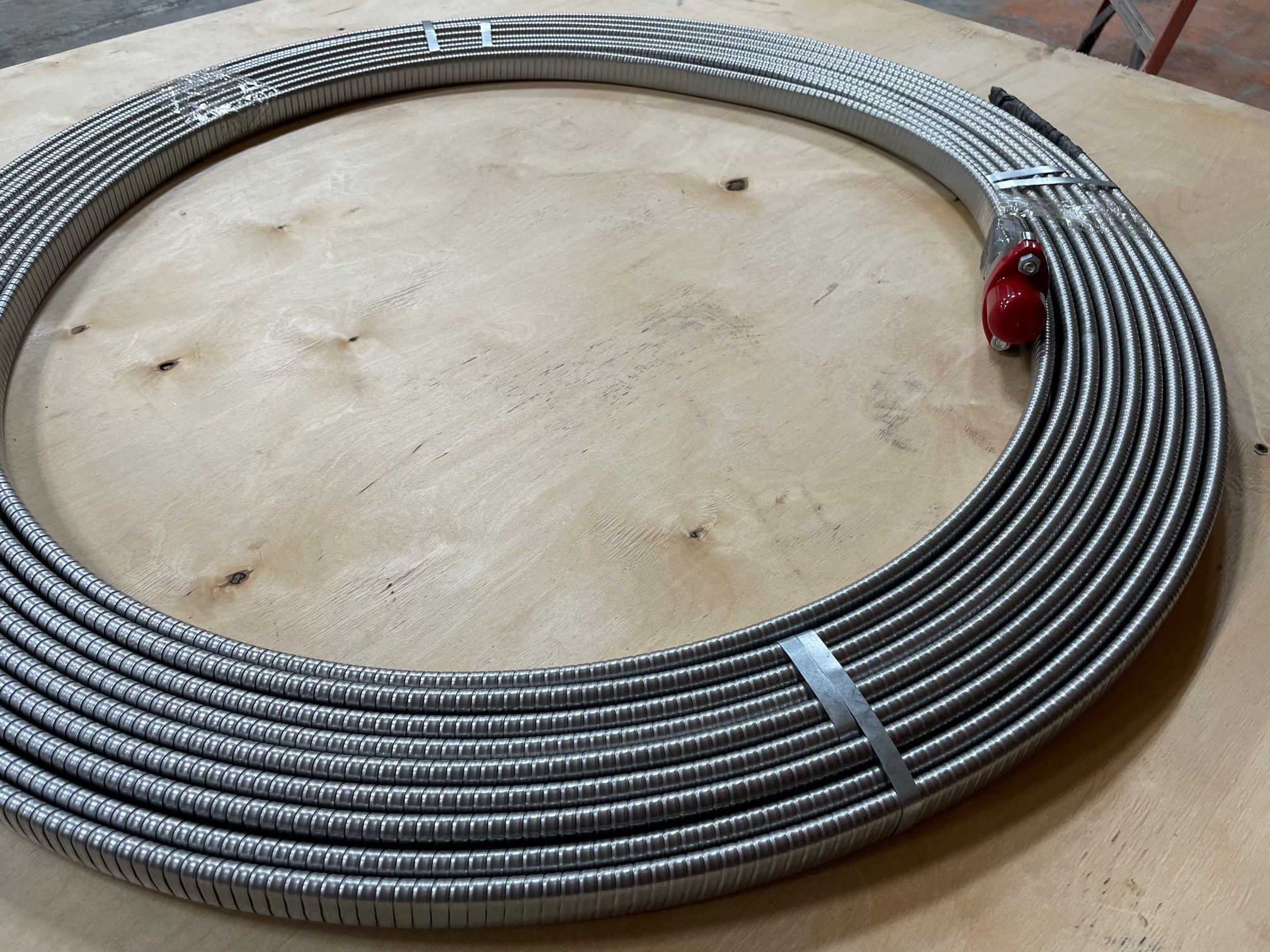

Electric Submersible Pump Cable

ESP Cable

A complete line of high-performance cables designed to the exact standards required for electric submersible pumping systems. Maximize operational longevity, with Slyder cables which are tested to the latest API and IEEE recommended practices, as well as the stringent specifications for each specific line.

Slyder’s EPDM (ethylene propylene diene monomer) cable uses an insulation compound specially formulated to be oil-resistant while maintaining excellent electrical properties. For additional protection, a lead or an additional EPDM jacket is applied over the insulation to add strength and provide an added shield to the insulation.

All of Slyder’s three-conductor EPDM cables can be customized for specific well conditions requiring different armor materials.

Download

Slyder Services Brochure